Servo motors drive the traverse part, the crosswise part of the finished arm, the crosswise part of the nozzle arm, the down part of the finished arm and the down part of the nozzle arm, with different cross out and down positions. In the injection molding machine injection molding products and mold, the mechanical hand can automatically and accurately take out the product and the nozzle, can be placed in a number of points, can be arranged in order, circulation of goods, will not cause product deformation, will not touch the surface, and can achieve automatic packing and labeling within the mold and other precision requirements. The utility model has the advantages of simple structure, fast extraction speed, high efficiency, small vibration, high precision and long service life. In this way, the production capacity can be increased by 20%-30%, the defect rate of product cost can be reduced, the safety of operators can be guaranteed, and the labor and waste can be reduced.

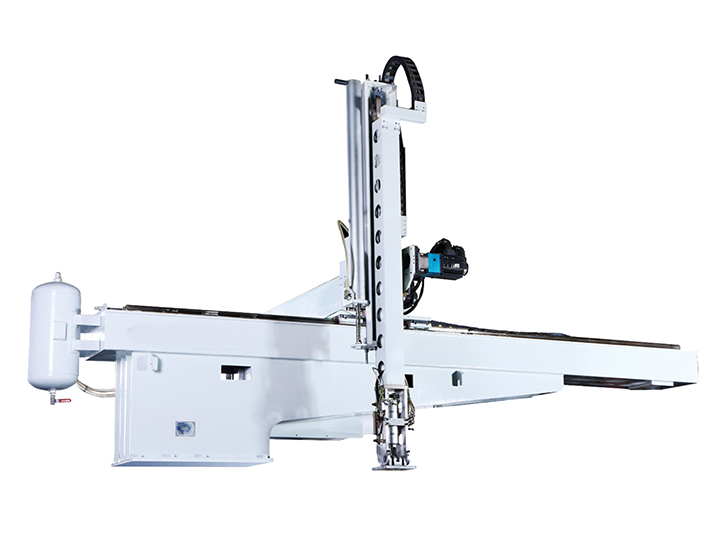

(Product display)

· N type crosswalk servo manipulator is suitable for all types of horizontal injection molding machines with 30 ~ 4000 tons. Are 3 axis servo drive. The upper and lower arms are of double-section structure, with the travel specifications ranging from 750mm to 3000mm. Installation of this series of manipulator can increase productivity (20 ~ 30%), reduce the defective rate of products, ensure the safety of operators, reduce labor and waste.

· body structure: high precision linear slide rail is used for transverse, drawing and upper and lower axes, with long wear resistance and life. The upper and lower arms use high steel structural beam, special belt double speed mechanism design, can greatly shorten the structural height of the upper and lower arms, in addition to increase the speed and stability of the upper and lower stroke, and can cooperate with the plant in low height.

· operating system: handheld operator, friendly interface, exchange of Chinese and English, easy to learn, multiple functions and procedures for selection, can be automatic, manual, 64 sets of mold memory, mold change operation setting is simple, automatic fault detection, display on the screen, convenient adjustment.

Side pose chamfering mechanism: the fixed Angle 90 °, can cooperate with the male die cavities and remove.

· jig: suction cup or holder can be selected according to the need. The jig loop is reserved for two suction and two hold four loops, which can be used for the removal of jig such as suction clamp, and can be used for the removal of various finished products.